MindMap | English Study

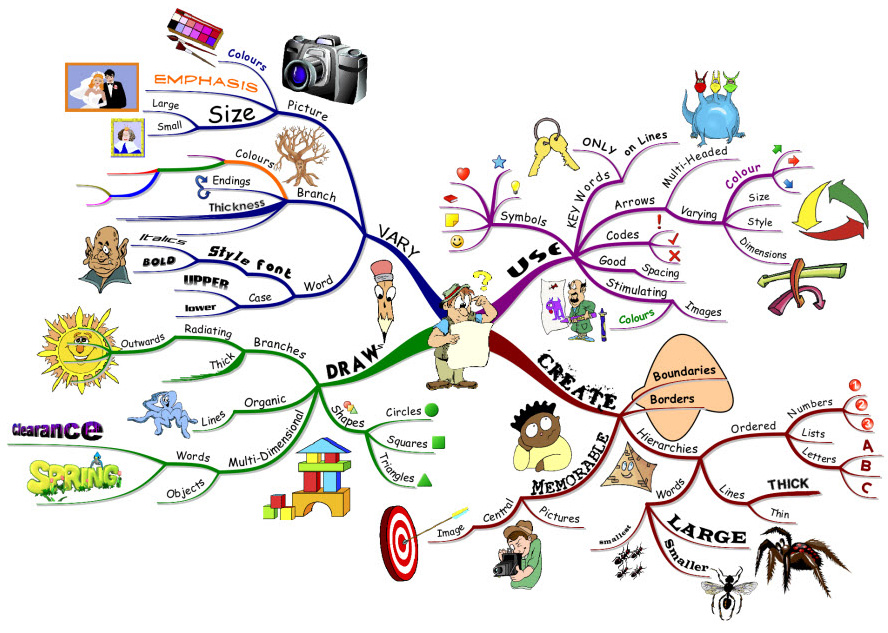

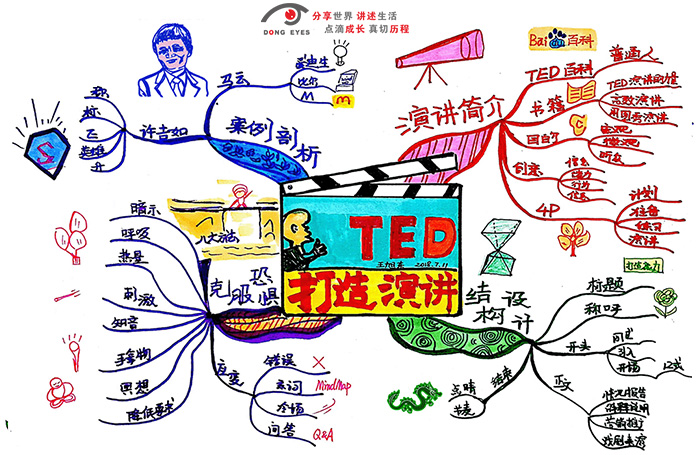

思维导图与英语学习,杨老师通过深入浅出的方式将思维导图工具应用到英语学习中,给我们一种快乐学习的美好体验。后面又通过简单应用、复杂应用和教学应用渐次深入的应用思维导图这个工具。

思维导图与英语学习

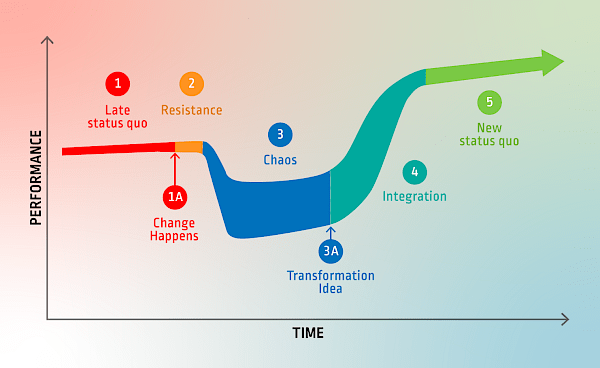

快乐学习

学习的时候要心无杂念,一丝不苟;玩的时候要尽情玩耍,把一切烦恼抛诸脑后。尽情放松,玩耍和放松后回来高效,轻松的利用学习技巧学习,才能提高学习效率,更可以提高学习的成绩。

简单应用

通过思维导图速记单词,音素与单词,音标、音素与单词,通过不同场合与场景中的应用,体现思维导图的图像化思维,全脑思维,让孩子的学习更容易,记忆更深刻。

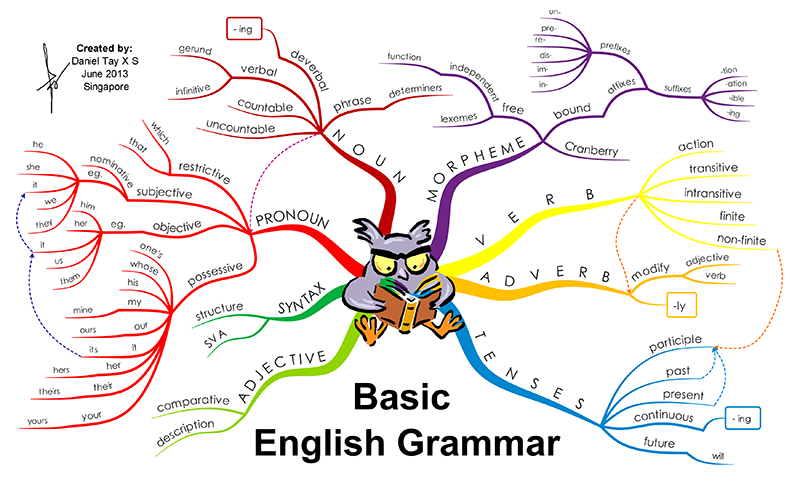

英语基础语法导图

复杂应用

更深一层次的复杂应用,讲述了思维导图与语法学习,思维导图与句型学习,思维导图与阅读,思维导图与书籍汇总等。将思维导图与日常的应用学些的各方面有机结合深入学习。

基本掌握了思维导图绘制的相应技巧,需要绘制更多的导图来练习和熟练相应技巧,以达到灵活运用的阶段。